ATEX

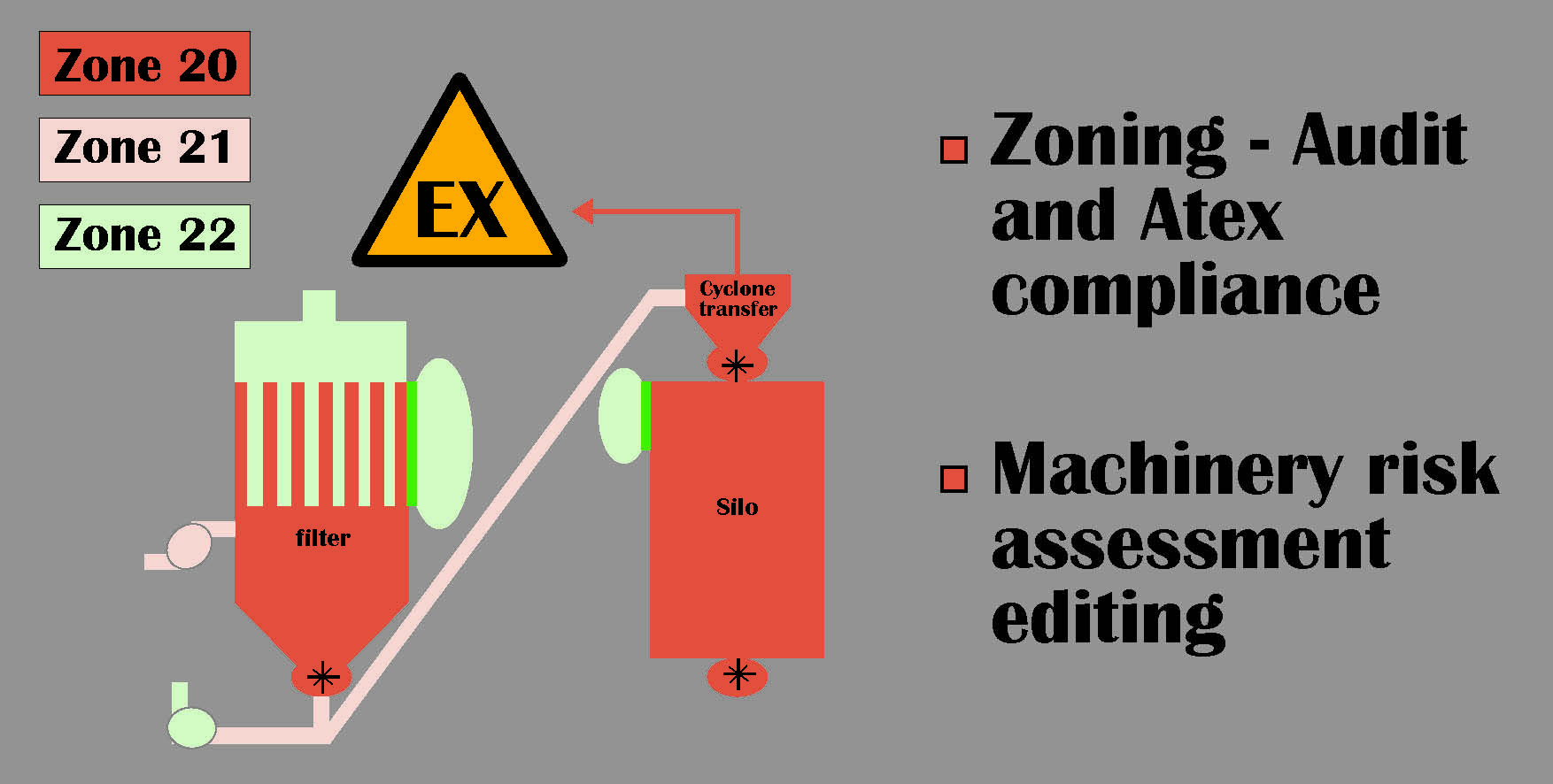

2 Atex services :

|

|

Our know how :

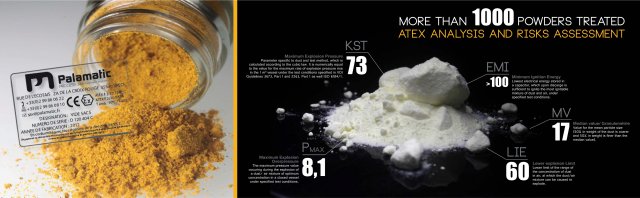

Palamatic Process is specialized in developing and manufacturing machines and systems for the production of food and feed, chemical and fine chemical products.

In their production processes, our customers are very frequently faced with the explosive nature of several materials used (powder, gas, liquid). Huge accidents prove the consequences that an explosion may have. When the atmosphere is explosive, a small spark (e.g. that of an electric switch or from the mechanical heating of a part of the machine) is enough to cause an accident or a disaster.

For many years, authorities and industries have worked on developing safety rules governing work conditions in such dangerous environments : explosive atmospheres. The new regulations, called ATEX regulations, were published and are effective as from 1st July, 2003. Today, Palamatic Process provides its expertise to classify your risk zones based on the nature, frequency or duration of the presence of an ATEX regulation. Marked explosion risk zones are signalled with the warning sign established by regulation...

Palamatic Process defines with you the protection and prevention steps to be adopted, considering your restrictions. A document referring to explosion protection will be established and integrated into the Occupational Risk Evaluation Unique Document.

GUIDELINES

Reminder of the guidelines:

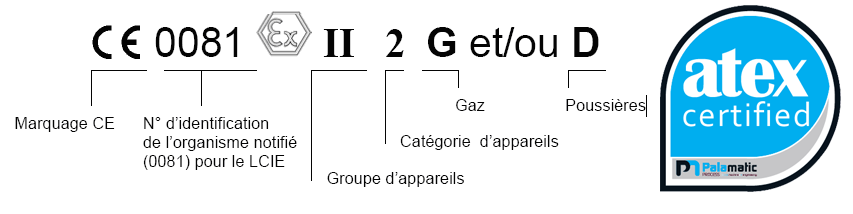

As of 1 July 2003, all manufacturers concerned with the manufacturing, use or distribution of materials must comply with the essential requirements of health and safety provided by these two directives.

- Directive 94/9/EC:

It regards the free circulation of equipment when placed on the market.

It is intended for designers of equipment for use in explosive atmospheres.

- Directive 1999/92/EC:

It relates to safety of workers at the workplace relative to the risk of explosion.

It is intended for users and establishes minimum requirements to be met by the manager regarding safety of workers who may be exposed to explosive atmospheres.

It requires a classification of areas and carry out compliance of the facility.

- Definition of an explosive atmosphere (ATEX):

ATEX is a "mixture with air, under atmospheric conditions, of flammable substances in the form of gases, vapors, mists or dusts in which, after ignition has occurred, combustion spreads to the entire unburned mixture".

It should be noted that ATEX can exist:

- In an open environment: the inflammation will create essentially a thermal effect

- In a closed environment: its inflammation will create thermal effects and pressure effects

CLASSIFICATION

ZONING FOR DUST

Zone 22

A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

For example, zone 22 locations may be, among others, locations around equipment containing powder, when dust leaks may occur due to dustproof defects, and build up dust in dangerous amounts.

Zone 21

A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur in normal operation occasionally.

For example, zone 21 locations may be, among others, areas around dust evacuation devices or loading stations and areas with dust deposits likely to form occasionally, in normal operation, an explosive concentration of combustible dusts mixed with air.

Zone 20

A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is present continuously, for long periods, or frequently.

For example, these conditions are generally expressed only inside containers, pipes, equipment, etc. The zone is restricted, initially, to the interior of equipment (mills, dryers, mixers, backflow pipes, silos, etc.), when dangerous quantities of explosive mixes of dust are likely to form continuously, for long periods, or frequently.

ZONING FOR GAS

Zone 2

A place where an explosive atmosphere consisiting of a mixture with air of flammable substances in the form of gas, vapour or mist is not likely to occurin normal operation but, if it does occur, will persis for a short period only.

For example, zone 2 locations may be, among others, locations around zones 0 ou 1.

Comment: a place near pipes where flammable substances are conveyed only in pipes that are permanently dustproof technically is not considered to be dangerous locations.

Zone 1

A place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapour or mist is likely to occur in normal operation occasionally.

For example, zone 1 locations may be, among others :

- The environment around zone 0

- The environment around filling openings

- The area around fragile devices or pipes made of glass, ceramic or other similar materials, unless the content is such a small amount that it cannot constitute a dangerous explosive atmosphere

- The area around stuffing box not perfectly gas-proof, for example, around pumps or feeders

- The inside of equipment such as evaporators or reactors

Zone 0

A place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is present continuously or for long periods or frequently.

For example, in general, the conditions for zone 0 occur only inside containers or equipment (evaporator, reacteur, etc...), but they can also be present near venting areas and other openings.

SUMMARY

| ATEX likelihood | High | Medium and low | Very low | Unlikely |

| Duration of présence | > 1000 hours/yr | 10 < hours/yr < 1000 | 1 < hours/year < 10 | 1 < hour/year |

| Definitions | A place in which an explosive atmosphere is present continuously, for long periods, or frequently | A place in which an explosive atmosphere is likely to occur occasionally in normal operation | A place in which an explosive atmosphere is not likely to occur in normal operation but, if it does occur, will persist for a short period only (predictable normal operation) | Not dangerous location |

| Gas and vapours | Zone 0 | Zone 1 | Zone 2 | Out of area |

| Dust | Zone 20 | Zone 21 | Zone 22 | Out of area |

Example of marking code :